Polyurethane (PU) rollers manufacturers — Shibaam Polymers, Bengaluru, India

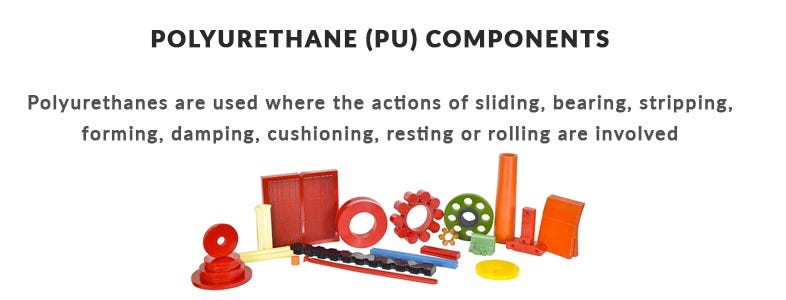

These are internationally popular for their high load bearing capacity, high impact strength, high abrasion resistance, high resilience and excellent resistance to oil and grease. The applications of polyurethanes include where the actions of sliding, bearing, stripping, forming, damping, cushioning, resting or rolling are involved. For optimum performance, better results and longer life, selection of appropriate grades is important. These can be formulated with permutation & combination of selective chemicals & additives. Cast Polyurethanes have unlimited running applications & a huge replacement market is waiting to turn on. Polyurethane (PU) is a combination of plastic and elasticity of rubber. Some of the features of cast polyurethane are: Cost effective, Dependable, Elastomers combining the performance advantages of engineering plastics, ceramics and metals, Resilience and flexible as rubber, High life expectancy Industries Used: Press tools, Jigs & fixtures, Conveyors, Machine tools Process Used In: Stripping, Forming, Damping, Cushioning, Resting or rolling Applications: Mining Industry, Pads, Abrasion Resistant Linings, Grar Seals, Jig & Fixtures, Mallets, Punch-strippers, Screens, Spacers, Rollers & Sleeves, Suspension Bushes, Scrappers Blades, Wheels, Wear Plates

Polyurethane (PU) rollers manufacturers — Shibaam Polymers, Bengaluru, India

Comments

Post a Comment